Innogeneration presentation video

A video summary of the event and the conferences !

BPI #InnoGeneration, a day of innovation

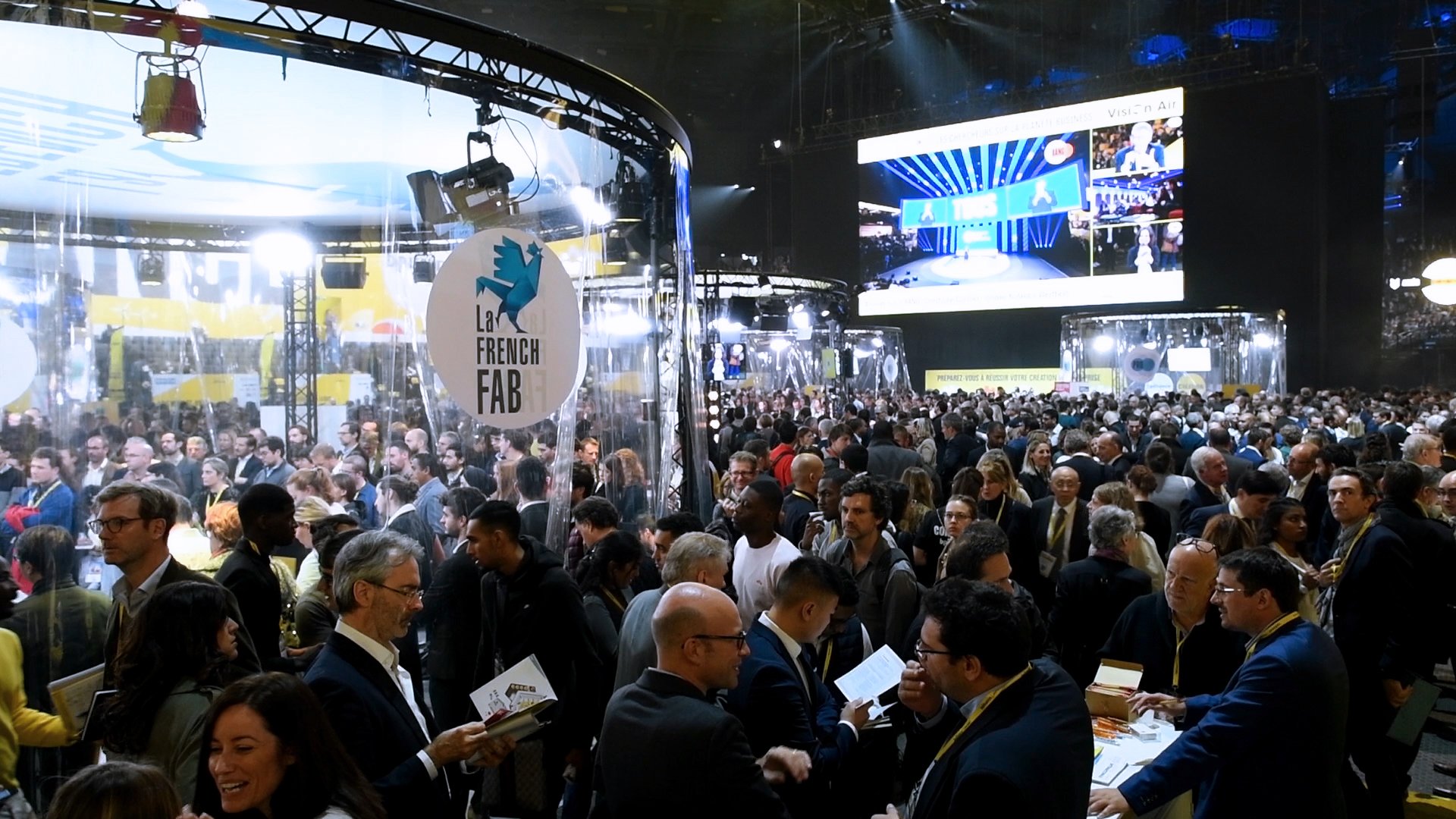

The poster looks beautiful, the BPI is promoting innovation through its event called the largest business gathering in Europe, in Paris this October 10. Planned contacts, workshops, lectures, masterclasses and well-known speakers on the stage.

A program on business transformation and artificial intelligence

With the application, I reserved in advance slots for conferences on digital transformation, industry 4.0 and masterclasses on artificial intelligence that particularly appeal to me, with the theme of the industrialization of AI: « organization and governance » and « Automation of algorithms ». I tried to connect with people there, but without much success.

On D-Day, when I arrived in the big room, I already have a good feeling because things are very prepared and with a real overall consistency in terms of colors and locations for the workshops. Just a downside to the fairly high temperature because of the lights in the pitches in the middle of the arena surrounded by plastic sheeting. However, they did their effect well by isolating the outside sound and allowing the speakers to listen calmly enough.

My negative point concerned the InnoGeneration masterclasses which were totally overbooked, and I could not participate because only 15 people could enter. I had booked correctly, but you had to show up more than 30 minutes before to hope to get in. So, exit for all sessions on artificial intelligence and that’s a shame.

Industry of the future : how to make your digital shift a success

Speakers : Visiatiz and Dassault Systems

Leaders, be the leader of your transformation

This first workshop seemed promising enough, where the main points of attention to succeed in its transformation were presented. They talked about cross-cutting transformation and the importance of the human dimension in this transformation. It is of course the leader who must take charge of this transformation and who cannot delegate this mission because it brings together all the dimensions of the company. The whole value creation process is to be put on the table to find out how it needs to evolve.

If you want to delve deeper into the subject of the leader 4.0, it’s here !

A Legacy as a Legacy

The technological directions must be consistent, the company already has existing systems and must deal with them. The best practice will be to map the existing one in order to know what to manage before adding new layers of technology.

In a disruptive approach to transformation, make a complex or risky return on investment calculation. Indeed, working in a totally new way is always difficult to estimate in terms of costs, is the target business model viable ? Will the sales forecast be realistic ?

The tool is not the problem, the human is the solution.

Achieving the evolution of human behaviour is the most time-taking, it must be kept in mind. It is thanks to the men and women of the company that your well-prepared transformation plan will be a success or a failure, so you have to take into account the « change management » dimension if you want to succeed.

Bringing industrial know-how together for greater agility

Speakers : Sculpteo & Dassault Systems

The additive manufacturing, Sculpteo pitch

As a specialist in additive manufacturing for more than 10 years, its CEO is driven by the vision of a fully connected factory: buying products over the internet, automating factory manufacturing and delivering customers directly to their homes. Nice ambition. I particularly remember their desire to remain « technologically agnostic » to avoid falling into the traps of specialization and to continue to keep varied choices. The life cycle of its products is quite radically different from what can be found elsewhere : the very small series generates specific commercial and administrative constraints.

Becoming an « Amazon » of 3D printing

Dassault highlighted 3 of its online services that aim to connect industrial ecosystems and bring companies together.

✔ A “Manufacturing as a Service” with 200 suppliers to cover different types of needs.

✔ A « Design and Engineering as a Service » for 3D modeling for example.

✔ A « Components as a service » that already has more than 30 million components.

In note, attention must be paid to the « Intellectual Property » dimension and « Quality » because the industrial validation of this type of parts must be as rigorous as a more traditional piece.

Industry of the future: the example of a FrenchFab collaboration

Speakers : JPB System & Sodistra

Two experienced speakers with a clear view of the industry 4.0

I really liked this speech which gave a great example of transformation towards industry 4.0 with the return of two business leaders motivated to promote #LaFrenchFab and #LaFrenchTech. Its leader is a former electronics engineer who took over the family company in mechanics. The mix of skills is always a source of innovation, this is yet another example. JPB System has completely overhauled its value creation process, and shared its start-up production difficulties, 30% below the old approach, before re-overtaking the bar by a wide margin thanks to a work of optimization of new digital tools and uses.

An agri-food factory that perseveres in its transformation

Hearing a business leader talk about his perseverance in digital transformation, his difficulties and how he manages to get by is very inspiring. He found his solution in sharing knowledge and working with other entrepreneurs as part of #LaFrenchFab pour accélérer sa transformation et trouver les clés pour avancer vers ses objectifs.

The language of the machine can be a universal language

It is always difficult to find a way to connect machines together. We find ourselves faced with different languages, different versions of the operating system, incompatible or obsolete hardware… The list is long. However, it seems that a common language can be found through the sound that machines make, which allows to understand their speed of production or possible failures. Based on these technologies and artificial intelligence, Keyprod will be launched soon in 2020.

What future is desirable for your company ?

Speakers : CETIM

How to draw up a plan for human and technological transformation

The first step will be to mobilize the teams so that they can take ownership of the transformation of their company, because it will be necessary to reposition the mission and vision of this company itself so that it can really transform itself. Knowing your strengths, weaknesses and knowing how to take stock of your situation is critical to being able to project yourself into the future.

There is no operational excellence without economic efficiency.

A common-sense word when the speaker stated that the company must think about its economic profitability in order to achieve operational excellence and meet its environmental and societal commitment. The subject of the integration of new technologies is only one dimension of the transformation of the company.

Skills and knowledge of the leader are key to the transformation of their company

Digital transformation is still considered by many entrepreneurs to be complex, and according to a questionnaire from Dassault Systems, 87% of SME and ETI leaders still believe that digital transformation is not a priority in 2019. It is true that fast-growing companies are more advanced in their transformation than those with shorter-term problems to manage. However, we should not wait until we are in crisis to think about it, because the risk will be to see this transformation as a single way to reduce or optimize its costs. The company will therefore miss the most important : the subject of the value carried by the company to its customers.